Often, vessels bunkering in the US scoff at the idea of paying for a bunker quantity survey (BQS). Typically this rationale stems from two related ideologies: 1) US bunker fuel is heavily regulated; thus the chance of significant loss is negligible, and 2) bunker operations are highly standardized; therefore the likelihood of unethical behavior and pilferage is also insignificant.

Both statements, in this case, are valid for the most part (in the US). However, this is operating under the assumption that only these two factors would significantly affect barge to vessel variances. More often than not, while the operations and procedures are regulated and standardized, there are several other variables, both quantitative and qualitative, which could result in a significant barge to vessel variance.

Quantitative assessments:

Unlike in other parts of the world, pilferage of bunker fuel is rare when bunkering in the US. However, quantitative variables such as temperature change, methods of measurement, and density calculations, while seemingly small, can have substantial impacts on the delivered quantities. Typically barges load several hours (or days in some cases) before delivery to a subject vessel, and BDN stats reflect the variables measured at the time of loading. Very rarely would barge personnel recalculate these variables just before delivery as it typically would not affect their bottom line: they load a specific quantity and state that amount as delivered. If those variables changed (which often they do) the real variance can be significant.

Qualitative assessment:

Beyond the numbers, there lie subjective and conditional variables which could affect final delivered quantities. These often hinder from a cost to benefit ratio. If a particular practice, say averaging temperatures for all tanks, saves enough time, more likely than not it would be done. Human error can have significant impacts in this case if say the averages were not weighted. Another such variable would be the supply chain of custody. Local surveyors typically know non-public information about certain loading ports and barges. This information could help mitigate certain known issues which are often overlooked. I.E. new trim tables, known calibration errors, etc.

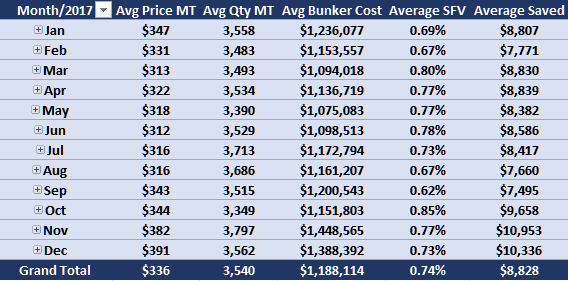

By taking both qualitative and quantitative factors to mind, SKK Marine Surveyors can effectively mitigate bunker fuel loss. Through our well established and positive relationships with all key stakeholders, we can ensure the bunker operation is both smooth an accurate. The graphic below shows data for 2017 in bunker operations in which we were involved. This data is an aggregate of four US ports: Los Angeles/Long Beach, Oakland, Seattle, and Houston. Our key variable, SFV (Surveyor Favorable Variance) is the percentage in which we found favorable variances through quantitative adjustment (>90% of the time), qualitative intervention, and accounting claims.

On average, we save our clients $8,828 USD per bunker operation, which averages to an annual average savings of $1,544,940 USD on bunker costs.

On average, we save our clients $8,828 USD per bunker operation, which averages to an annual average savings of $1,544,940 USD on bunker costs.

With those figures, it is clear that a bunker quantity survey is almost always a cost-reducing service.