Authored By: Khan, S., Mateus, F.

Date of Publication: 2021 – March – 03

Introduction

In liquid cargo management, the quest for precision in volume measurement is not just a necessity but the backbone of operational excellence and loss prevention. SFK stands at the forefront of this challenge, pioneering a benchmarking methodology that propels accuracy and reliability to unprecedented levels. This review elucidates our innovative approach, which marries the rich insights derived from historical data with the precision of advanced mathematical modeling. Together, they forge a methodology that not only addresses but also anticipates the nuanced challenges intrinsic to maritime and storage tank operations.

Historically, our industry has grappled with the limitations of traditional measurement techniques, often leading to significant financial discrepancies and operational inefficiencies. In this context, our innovative approach not only marks a departure from these conventional methods but also underscores our commitment to redefining industry standards and fostering a culture of continuous improvement and precision.

The Need for Precision

The intricacies of liquid cargo management unfurl a myriad of challenges, where the accuracy of volume measurement transcends operational necessity to become a cornerstone of financial integrity and strategic partnership. Disparities in volume measurements can cascade into substantial financial discrepancies, engender disputes, and, most critically, erode the bedrock of trust between trading partners. Our methodology is our bulwark against these challenges, an emblem of our dedication to redefining industry standards and nurturing a culture of continuous improvement and precision.

Our response to these challenges is a methodology that transcends traditional measurement paradigms. By leveraging sophisticated mathematical models and integrating comprehensive historical data, we not only meet but significantly surpass existing industry standards for accuracy and reliability. This section will illuminate the financial implications of measurement inaccuracies and delineate how our methodology adeptly addresses these challenges.

The Cost of Inaccuracy

Inaccuracies in volume measurement spell significant financial risks, from revenue losses due to underreported cargo volumes to contractual penalties and litigations. More insidiously, they corrode the trust that lubricates the gears of long-standing business relationships. Our methodology is a beacon of reliability, offering a shield against these perils by setting new benchmarks in measurement accuracy that far exceed traditional standards.

SFK’s Benchmarking Methodology

Historical Data Integration

At the heart of our benchmarking methodology lies the meticulous integration of historical data. This phase is a testament to our commitment to precision, involving the exhaustive collection and analysis of abundant data from loading and discharge operations spanning various geographical locales and operational conditions. This rich vein of historical data encompasses a vast spectrum of variables, including the type of liquid cargo, ambient and cargo temperatures, pressures, and the precise conditions under which these operations were conducted.

The process of historical data integration is underpinned by our strategic approach to data curation, where every piece of data is scrutinized for its integrity, relevance, and accuracy. We employ advanced data analytics tools and methodologies to sift through this vast dataset, identifying patterns, anomalies, and trends that are instrumental in constructing a comprehensive understanding of the intricacies involved in tank volume measurement. This painstaking effort ensures that the dataset is not merely a collection of numbers but a rich tapestry of operational insights that reflect the real-world complexities of liquid cargo transfer.

Moreover, historical data serves as a critical reference point for benchmarking current operations. By establishing a baseline of past performances and outcomes, we can apply a comparative lens to evaluate the efficacy of current measurement techniques. This approach not only facilitates a rigorous assessment of the present methodologies but also illuminates pathways for continuous improvement and innovation.

One of the hallmark features of this integration process is its adaptability and scalability. As new data is continuously generated from ongoing operations, the historical dataset evolves, becoming ever more comprehensive and nuanced. This dynamic nature of data integration allows for the recalibration and refinement of our benchmarking models, ensuring that they remain highly accurate and reflective of the current operational realities.

Furthermore, the integration of historical data plays a pivotal role in enhancing future measurement accuracy. By leveraging this rich dataset, we are able to employ sophisticated mathematical modeling techniques to predict and simulate the outcomes of various operational scenarios. This predictive capability not only aids in optimizing operational strategies but also significantly reduces the potential for measurement discrepancies, thereby safeguarding against financial risks and reinforcing the trust between trading partners.

In essence, the Historical Data Integration phase is not just a preliminary step in our benchmarking methodology but a continuous process that lies at the heart of our success. It encapsulates our dedication to leveraging empirical evidence for driving precision, ensuring that each tank volume measurement is not only accurate but also a reflection of our unwavering commitment to excellence and innovation in liquid cargo management.

The Role of Temperature

Temperature plays a pivotal role in determining the observed volume of cargo. Our methodology sets rigorous temperature benchmarks to account for deviations in observed quantities before converting to calculated masses. This includes a close examination of the alignment between ambient, seawater, and product temperatures and their collective impact on the cargo’s volume. The goal is to ensure that any temperature delta from loading to the initial survey falls within established benchmarks, accounting for the calculated rate of change of the product temperature over time. This process, though complex, is crucial for predicting volume variances with a high degree of accuracy.

Advanced Mathematical Modeling

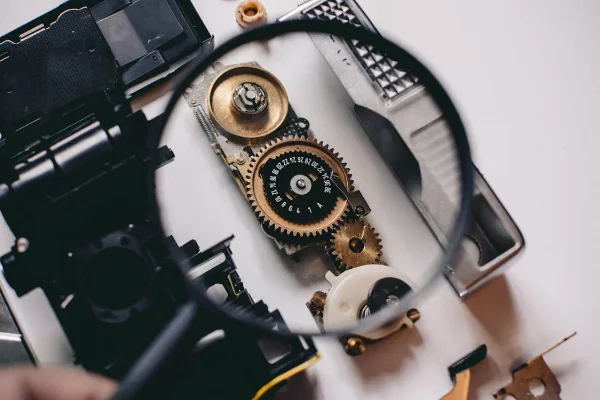

The crux of our approach is advanced mathematical modeling, a domain where SFK’s prowess truly shines. We employ sophisticated mathematical techniques to intricately map and understand the complexities of tank geometries and the dynamic behavior of liquid cargo. This involves considering the structural characteristics of tanks, such as shape, size, and construction material, and how they influence the liquid’s static and dynamic states. Environmental variables, including temperature fluctuations and pressure changes, alongside the cargo’s physical properties (density, viscosity), are integral to our models.

Predictive Power and Operational Strategy

Our models are not static; they are dynamic entities refined over time with new data, enhancing their predictive power. This allows for the optimization of operational strategies, reducing potential discrepancies and underpinning our commitment to financial integrity and trust between trading partners.

The Genesis of Modeling Complexity

The design and application of these mathematical models begin with a comprehensive analysis of tank specifications and operational parameters. Our team of mathematicians and engineers collaboratively develop algorithms that account for the myriad factors influencing liquid cargo volumes. These factors include, but are not limited to, the tank’s structural characteristics, such as shape, size, and construction material, which can affect the liquid’s static and dynamic states. Additionally, the models incorporate environmental variables like temperature fluctuations, pressure changes, and the cargo’s physical properties, including density and viscosity, which are crucial for accurate volume estimation.

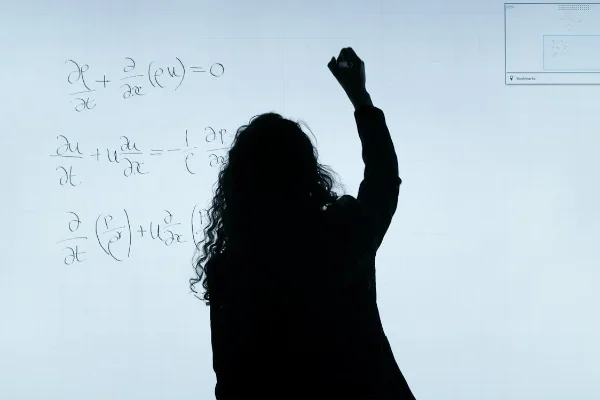

Advanced Techniques in Modeling

The mathematical models employed in our methodology leverage a variety of advanced techniques, including differential equations to model the fluid’s behavior within tanks under different conditions and statistical models to analyze and predict variations in measurement outcomes based on historical data. Computational fluid dynamics (CFD) simulations play a significant role, offering detailed visualizations and analyses of how liquid movements within tanks can affect volume measurements. This multifaceted approach enables the creation of highly accurate, predictive models that can simulate a wide range of scenarios, from routine operations to uncommon events, ensuring preparedness and precision in all circumstances.

Integration with Empirical Data

A critical component of the mathematical modeling process is the seamless integration with empirical data collected during the historical data integration phase. This confluence of theoretical modeling and real-world data ensures that the models are not only mathematically robust but also grounded in the operational realities of liquid cargo management. By continuously refining the models with incoming data, we ensure that the methodology evolves in lockstep with changing operational environments and technological advancements.

Continuous Refinement for Precision

The iterative nature of our mathematical modeling process allows for continuous refinement and enhancement. Feedback mechanisms are integrated within the methodology, enabling model adjustments and optimizations based on performance evaluations against actual measurements. This process of perpetual improvement ensures that the models remain at the cutting edge of accuracy and reliability, reflecting our commitment to excellence and our pioneering role in the industry.

Impact and Applications

The practical applications of these mathematical models are wide-ranging and transformative. They enable us to provide stakeholders with precise, reliable volume measurements that are critical for operational planning, financial forecasting, and strategic decision-making. Moreover, the insights gained from these models inform the development of best practices, optimization of cargo loading and unloading operations, and advancements in tank design and construction, further contributing to the industry’s overall efficiency and sustainability.

In essence, the mathematical modeling phase is a testament to our innovative spirit and technical prowess. By embracing and advancing the application of sophisticated mathematical techniques, we not only set new standards in volume measurement accuracy but also reinforced our leadership in addressing the complex challenges faced by the maritime and storage tank industries.

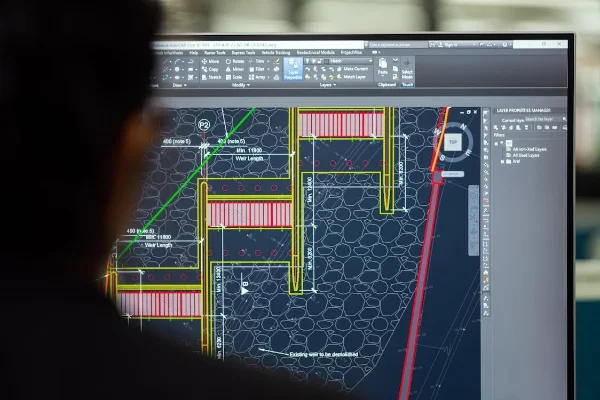

Verification and Cross-Referencing

Verification and cross-referencing stand as critical components in our benchmarking methodology, ensuring the integrity and accuracy of our volume measurements. This phase involves a rigorous process where the volumes calculated through our advanced mathematical models are meticulously compared against documented physical quantities. Such comparisons are not taken lightly; they are methodically aligned with tanks’ strapping tables—which detail the volume capacities at various levels—ensuring each measurement’s precision is grounded in empirical evidence. Sales receipts (I.E., BDNs, etc.), serving as definitive records of the agreed upon volumes delivered or received, also play a pivotal role in this verification process, offering an additional layer of validation to the calculated figures.

This dual approach is crucial, involving a rigorous comparison of volumes calculated through our models against documented physical quantities. This step ensures that our measurements are not only accurate but verifiable, reinforcing the trust our clients place in us.

Continuous Refinement

The benchmarking methodology is subject to continuous refinement. New data and operational feedback loop back into our system, allowing for perpetual enhancements that keep our methods at the cutting edge of precision and reliability.

Addressing Emerging Challenges

SFK is not content with merely keeping pace; we aim to set the pace. Our proactive development and refinement of benchmarks are designed to fill the ‘gray areas’ left by traditional standards. By addressing both the well-trodden and the less charted territories of cargo handling, we not only elevate our internal standards but also contribute significantly to the evolution of industry-wide practices.

Innovations and Industry Contributions

Our efforts to pioneer more accurate and up-to-date benchmarks underscore our leadership in navigating the complexities of liquid cargo transportation. We continuously integrate new data from both case studies and real world operations, ensuring that our benchmarks remain relevant and reflective of real-world scenarios. This commitment to innovation and precision ensures the best outcomes for all stakeholders, leading the way in refining best practices for the future.

Bridging the Gap with New Benchmarks

In recognizing that generally accepted industry standards can be slow to adapt to the rapid advancements and emerging challenges in cargo management, SFK takes a proactive stance. We develop innovative benchmarking practices that not only align with existing standards but also introduce more precise and relevant benchmarks. These new benchmarks are tailored to address specific challenges encountered in liquid cargo management, such as the nuanced effects of temperature and pressure on liquid cargoes, the peculiarities of different cargo types, and the idiosyncratic conditions of various storage and transport scenarios.

Integration of Historical Data and Mathematical Modeling

The harmonious integration of historical data with mathematical modeling is the cornerstone of our methodology. This integration is not static; it is a dynamic, evolving process that continuously adapts to new insights and operational realities. The fusion of empirical data with analytical precision enables us to predict outcomes with a high degree of accuracy, optimize operational strategies, and ultimately, enhance the efficiency and reliability of liquid cargo management.

From Data to Decision-making

The practical implications of this integrated approach are profound. By providing stakeholders with precise, reliable volume measurements, we enable better operational planning, financial forecasting, and strategic decision-making. The insights gained from our models inform the development of best practices, contribute to the optimization of cargo loading and unloading operations, and guide advancements in tank design and construction.

Benefits of the Benchmarking Approach

Our benchmarking methodology brings forth a multitude of benefits that revolutionize the approach to liquid cargo management. Beyond the significant improvement in measurement precision, this methodology fosters informed, data-driven decision-making, enhances operational efficiency, and provides a competitive edge in the industry.

A Culture of Precision and Improvement

By leading with this innovative benchmarking methodology, SFK not only sets new benchmarks for measurement accuracy but also fosters a culture of continuous improvement and technological advancement. This culture is pivotal for maintaining operational excellence and financial integrity within the liquid cargo management industry.

Conclusion and Future Directions

As SFK Corp looks to the future, we are committed to refining our benchmarking methodology, embracing cutting-edge technologies, and addressing the evolving challenges within the liquid cargo management industry. The potential integration of technologies such as Artificial Intelligence (AI) and the Internet of Things (IoT) presents exciting opportunities for enhancing precision, efficiency, and insight.

Shaping the Future

These technological advancements promise to augment our sophisticated mathematical models and data analysis capabilities, offering deeper insights, predictive analytics, and more automated decision-making processes. By integrating these technologies into our benchmarking methodology, SFK will continue to lead the industry in precision, innovation, and operational excellence.

SFK Corp stands not merely in response to the future but as an active architect of it, ensuring that our benchmarking methodology remains the gold standard in the industry. Our ongoing exploration of new technologies and methodologies signifies our unwavering commitment to innovation, accuracy, and excellence, securing our position at the forefront of the maritime and storage tank industries.